BNSF roadmaster’s team points the way toward safety

By JEREMIAH VALENTINE

Staff Writer

Cameron Henderson remembers the exact day his safety approach changed.

“I was on a conference call to discuss an incident that could and should have been avoided,” Henderson said. “Luckily no one was hurt.” That’s when Henderson, a roadmaster based in Vancouver, Washington, reflected on his own learning style. He questioned, as a team, what can we do better?

Doing some research, Henderson learned that 65 percent of people are visual learners. He began wondering how to better integrate aspects of visual learning into BNSF’s safety programs.

“If I read a manual, even out loud, only a small amount of the population (35 percent will absorb it because they are audible learners,” he said. “However, when I point my finger in a direction to help communicate instructions, I say it out loud, and they follow along while I am reading it, three types of learning are covered at the same time.”

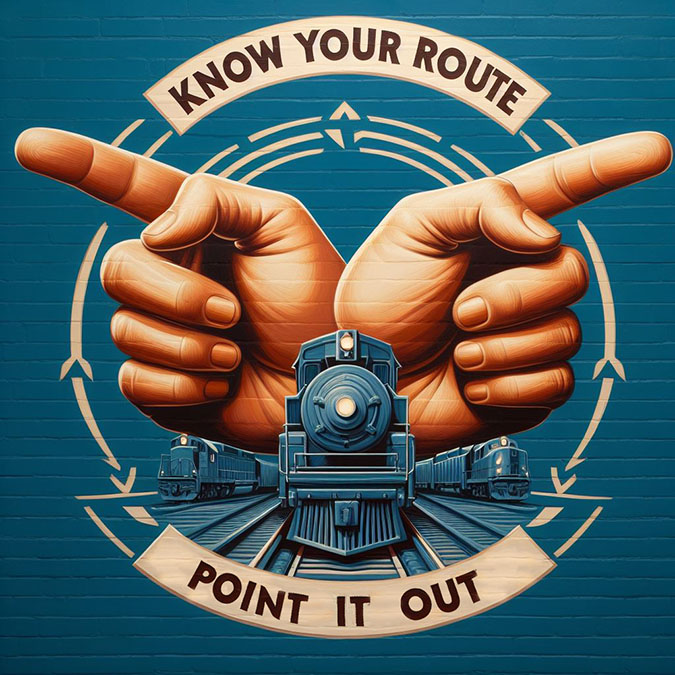

His entire team now uses this multi-sensory learning technique during their briefings, which is like the Shisa Kanko safety technique popularized by the Japanese rail operators. Henderson even made posters with the tagline “Know your route, point it out,” placing them around the office to remind the team of this technique.

The theme has taken off. Simple gesturing and pointing enhances clarity. “It’s easy to make a mistake,” he said. “This is a great way to help stay focused and eliminate confusion.”

Henderson also introduced pressure briefings, once again born from an issue arriving in the field. Pressure briefings help mitigate feelings of being overwhelmed on the job site.

“At any point in time, on any engineering crew, if anyone is getting overwhelmed or if they feel rushed, we encourage crew leads to pause the work, have a pressure brief, essentially re-briefing on what needs to happen,” he said.

Henderson’s methods are making a difference, with the Vancouver engineering team having gone more than four years injury-free -- the longest run they’ve ever had.

Safety is important to Henderson for many reasons, but one incident helps keep it all in perspective.

“When I was 21, I got into a dirt bike accident in the woods, and I spent seven months in the hospital with a five percent chance of survival. It was a life-changing event,” he said. “That made me realize there is a lot more to life than what is happening right now.”